Mango pulp production line introduction:

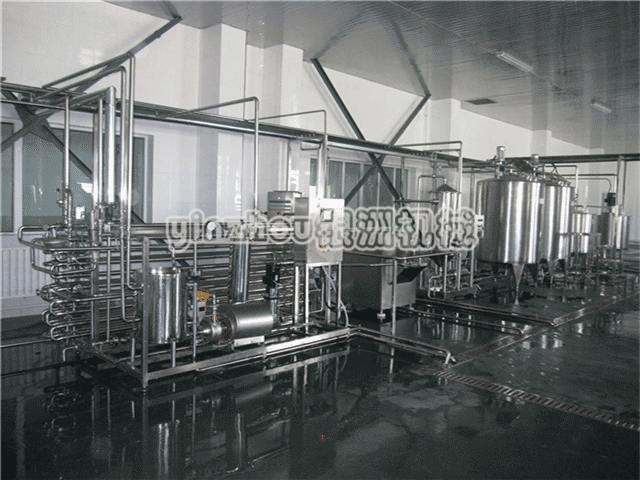

This production line is suitable for the processing of mango, pineapple and other tropical fruits.This production line is mainly composed of bubble cleaning machine, winding machine, inspection, MAO scrub fruit, fruit machine cutter, pre-cooking machine, peeling to nuclear beater, crusher, belt type juicing, separator, enrichment equipment, sterilization machine, filling machine equipment, etc.This production line design concept advanced, high degree of automation;The main equipment is all made of high quality stainless steel, which fully meets the hygienic requirements of food processing.

Mango juice production line technology:

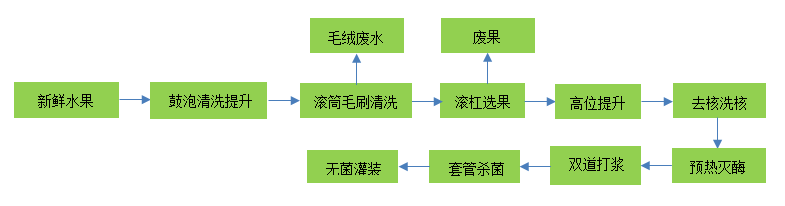

Raw material selection - cleaning - fruit picking - core-removing - preheating enzyme - pulping refining - concentration - blending - degassing - homogenization - sterilization - filling - finished product.It includes raw material pretreatment system, core removal and grouting system, concentrated evaporation system, distribution system, homogeneous degassing system and sterilization filling system.

Ingredients: fresh mango.

Products: concentrate, concentrate sauce, juice drinks, etc

Capacity: 10 tons/day -2500 tons/day

Juice yield: about 75% (25% fruit peel and kernel)

Material solid content: 10-12brix,

Final concentration of concentrate: 65~72Brix

Finished product packaging: sterile large bag/hall/glass bottle /PET bottle

Production/packaging form: customized/customer defined according to customer requirements

Features of mango pulp production line system:

* handling capacity ranges from 10 tons/day to 2,500 tons/day.

* add individual devices to handle fruits with similar characteristics, such as pineapple.

* improve the efficiency and rate of juicing by using the de-nucleated pulping machine.

* PLC control throughout the production process. All electrical components are imported products, saving labor and greatly reducing the difficulty of operation technology.

* low temperature vacuum concentration ensures flavor and nutrients and greatly saves energy.

* tube sterilization and aseptic filling to ensure the aseptic state of the product.

* with its own automatic cleaning system.

* the material contact part of the system is all 304 stainless steel, which fully meets the requirements of food hygiene and safety.

Mango processing process:

Related Products

News

- Xinjiang pepper paste production line 2018-06-02

- Russia jam processing line 2018-06-02

- Guangdong huizhou corn juice production line 2018-05-24

- Guizhou customer 10T/H prickly pear juice production line 2018-03-10

- Shandong customer two sets of UTH sterilization - aseptic filling equipment were delivered at the same time 2018-03-05

- Probiotics fermentation technology solves the problem of fruit and vegetable processing 2017-12-11

- The growth trend of the juice and beverage industry is slowing down 2017-12-04

- Global functional beverage development and new product development forecast 2017-07-28

- Technology and technological progress of food processing equipment are of great importance to environmental protection 2017-07-28

- Domestic and foreign dairy products preservation and disinfection technology 2017-07-28