Processing technology of cherry production line:

Raw material selection - cleaning - fruit picking - core removal - preheating enzyme - pulping refining - blending - degassing - homogenization - sterilization - filling - finished product.It includes raw material pretreatment system, core removal and grouting system, sterilization system, distribution system, homogeneous degassing system, filling system, etc.

Ingredients: fresh cherries.

Finished product: virgin pulp, cherry sauce, cherry juice beverage, etc

Capacity: 0.5-20 t/H

Pulp yield: about 75% (25% fruit peel and kernel)

Material solid content: 10-12brix,

Finished product packaging: sterile large bag/hall/glass bottle /PET bottle

Production/packaging form: customized/customer defined according to custom

Features of cherry processing production line system:

Features of cherry processing production line system: * add some equipment to handle fruits with similar characteristics, such as mango, peach, apricot, plum, etc.

* improve the efficiency and rate of juicing by using the de-nucleated pulping machine.

* PLC control throughout the production process. All electrical components are imported products, saving labor and greatly reducing the difficulty of operation technology.

* instant sterilization at high temperature to ensure flavor and nutrients.

* tube sterilization and aseptic filling to ensure the aseptic state of the product.

* with its own automatic cleaning system.

* the material contact part of the system is all 304 stainless steel, which fully meets the requirements of food hygiene and safety.

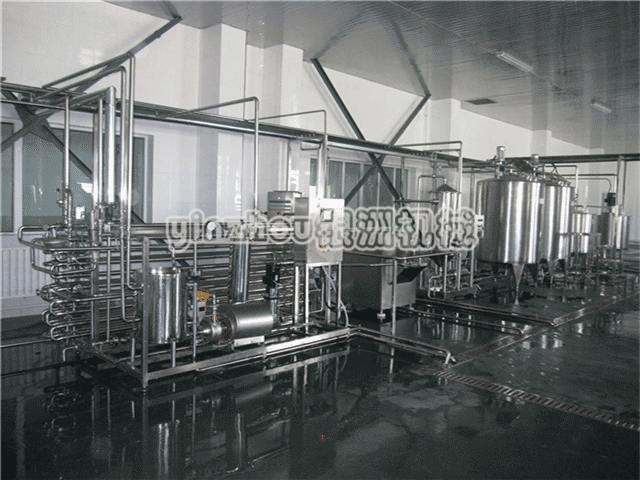

樱桃加工生产线现场图片:

Previous:Chili sauce processing line

Next:没有更多了

Related Products

News

- Xinjiang pepper paste production line 2018-06-02

- Russia jam processing line 2018-06-02

- Guangdong huizhou corn juice production line 2018-05-24

- Guizhou customer 10T/H prickly pear juice production line 2018-03-10

- Shandong customer two sets of UTH sterilization - aseptic filling equipment were delivered at the same time 2018-03-05

- Probiotics fermentation technology solves the problem of fruit and vegetable processing 2017-12-11

- The growth trend of the juice and beverage industry is slowing down 2017-12-04

- Global functional beverage development and new product development forecast 2017-07-28

- Technology and technological progress of food processing equipment are of great importance to environmental protection 2017-07-28

- Domestic and foreign dairy products preservation and disinfection technology 2017-07-28