position : Home> YINZHOU PRODUCTS> Single machine> sterilization equipments

Product introduction:

This company produces the tubular sterilizer for fruit juice, jam, milk or similar materials for sterilization processing, has good sterilization effect, reasonable structure, cover an area of an area small, easy to operate, etc.The equipment can be done at the same time to the function of heat sterilization and cooling of the material, at the same time can also to material sterilization temperature automatic control and record some important technical parameters, such as, both to reduce the influence of artificial factors on the sterilization process, at the same time can also record the normal production process.

The tube sterilizer can be divided into two types: row tube type and casing type.The casing sterilizer adopts four-layer casing structure, which is specially used for sterilizing various materials with poor liquidity and high viscosity, such as jam, pulp and malt dextrin.

The heat exchange pipe of the main part of the tube sterilizer adopts SUS304 high frequency welded thin-wall pipe or corrugated pipe.In addition, the main components used in this equipment are all made from the products of manufacturers with good materials and performance in the same trade, which ensures the performance of the equipment and makes users feel at ease.The application of sterilizer in food and beverage industry has the advantages of small energy consumption and low cost.

Configuration:

Tubular sterilizer is mainly composed of steam system, material system, hot water system, cooling system and so on several parts, and each part has collected together, compact structure, cover an area of an area small, easy to transport and install。

Operating principle:

After several processes, such as preheating, sterilization and cooling, the materials can be filled.Materials are heat exchanged with other media through thin - walled tubes.Material at a certain flow rate and velocity of flow in the pipe, and material for heat transfer medium, flowing in the outer casing material for heating or cooling, the temperature, flow rate, pressure change, all affect the effect of sterilization equipment.Or other external access steam, cooling water circulating water, etc., also must ensure that their pressure, flow rate, the stability of the temperature (for water), because of the change of these conditions will influence effect of sterilization equipment。

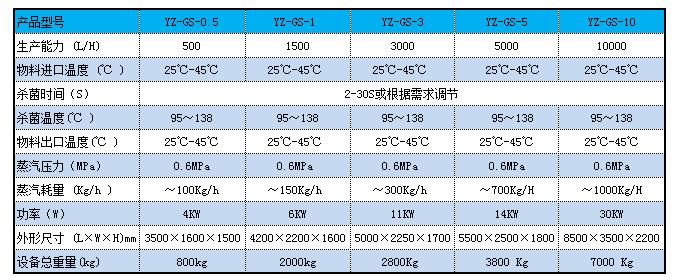

Basic parameter:

设备图片:

Previous:Water bath sterilizer

Next:Spray sterilizer

Related Products

News

- Xinjiang pepper paste production line 2018-06-02

- Russia jam processing line 2018-06-02

- Guangdong huizhou corn juice production line 2018-05-24

- Guizhou customer 10T/H prickly pear juice production line 2018-03-10

- Shandong customer two sets of UTH sterilization - aseptic filling equipment were delivered at the same time 2018-03-05

- Probiotics fermentation technology solves the problem of fruit and vegetable processing 2017-12-11

- The growth trend of the juice and beverage industry is slowing down 2017-12-04

- Global functional beverage development and new product development forecast 2017-07-28

- Technology and technological progress of food processing equipment are of great importance to environmental protection 2017-07-28

- Domestic and foreign dairy products preservation and disinfection technology 2017-07-28