position : Home> YINZHOU PRODUCTS> Single machine> sterilization equipments

Product introduction:

Column tube sterilizer is an ideal sterilizer for liquid drinks such as milk, fruit juice, vegetable juice, etc.High temperature and instant sterilization can be carried out on materials, and rapid sterilization can be carried out in a very short time to ensure that the nutrients of materials are not damaged, not lost, and the color of products is not changed.In addition to electrical configuration, motor and soft connection, the whole frame and pipeline are made of high quality stainless steel, and the preheating pipe, sterilizing pipe and cooling pipe are all seamless and high quality stainless steel

Description:

列管杀菌机可用于液态饮料食品无菌热处理系统,利用高精度的产品/水的温差控制,产品由平衡罐输入到换热器内,在加热部分与杀过菌的热物料进行换热后使冷物料温度升到预定值,然后通过由蒸汽加热的水间接加热到所需的杀菌温度,物料在持温管中维持所要求的温度一段时间进行超高温杀菌,从持温管出来后与进入机内的冷物料进行热交换,最后在冷却段冷却到预定的出口温度,整个过程均在封闭状态下进行,达到保证物料的生物稳定性的目的。并可根据用户对物料加热、保温、杀菌冷却的不同工艺要求进行特定的组合系统设计,以满足各类工艺要求。

列管杀菌系统主体分为:冷热物料热回收段、预热段、杀菌持温段、冷却段。整个杀菌过程全自动控制,人机界面可灵活设定杀菌温度。生产中杀菌温度上下温差波动不超过0.5℃.配带压力多功能罐,生产时候缓冲物料和物料回流,生产结束后可用做CIP清洗罐。本设备采用高配置,操作简单方便,设置好杀菌参数,一键式操作。自动完成杀菌过程,不需要人为干预。杀菌机采用冷热物料直接热交换实现升温和降温,比同行业相同杀菌机节能30%,杀菌机自带CIP清洗系统。

Equipments features:

Column tube sterilization machine can be used for the liquid beverage food aseptic heat treatment system, using high precision temperature control of product/water, the product by the balance tank into the heat exchanger, the heat of heat from the bacteria that kill the material after heat exchange materials make the cold temperature reaches the preset value and then indirectly through water heated by steam sterilization temperature, heated to required materials in a temperature to maintain the required temperature for a period of time in the ultra high temperature sterilization, from a tube temperature after heat exchange with cold material into the machine, the last in the outlet temperature of the cooling section cooled to a predetermined, the whole process are conducted in a closed state,To ensure the biological stability of materials.And can according to the user heating, heat preservation, sterilization cooling different process requirements for specific combination system design, to meet various process requirements.

The main body of the sterilization system consists of: heat recovery section of cold and hot materials, preheating section, sterilization holding section and cooling section.The whole process of sterilization is fully automatic control, the man-machine interface can set the sterilization temperature flexibly.Sterilization temperature and temperature fluctuation in the production of no more than 0.5 ℃. Equipped with multi-function pressure tank, production when the buffer material and the material flow, after the production can be used as CIP cleaning

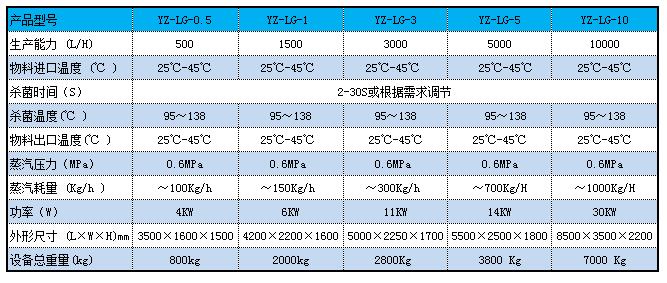

Basic parameters:

设备图片:

Previous:Spray sterilizer

Related Products

News

- Xinjiang pepper paste production line 2018-06-02

- Russia jam processing line 2018-06-02

- Guangdong huizhou corn juice production line 2018-05-24

- Guizhou customer 10T/H prickly pear juice production line 2018-03-10

- Shandong customer two sets of UTH sterilization - aseptic filling equipment were delivered at the same time 2018-03-05

- Probiotics fermentation technology solves the problem of fruit and vegetable processing 2017-12-11

- The growth trend of the juice and beverage industry is slowing down 2017-12-04

- Global functional beverage development and new product development forecast 2017-07-28

- Technology and technological progress of food processing equipment are of great importance to environmental protection 2017-07-28

- Domestic and foreign dairy products preservation and disinfection technology 2017-07-28